Diaphragm Walls

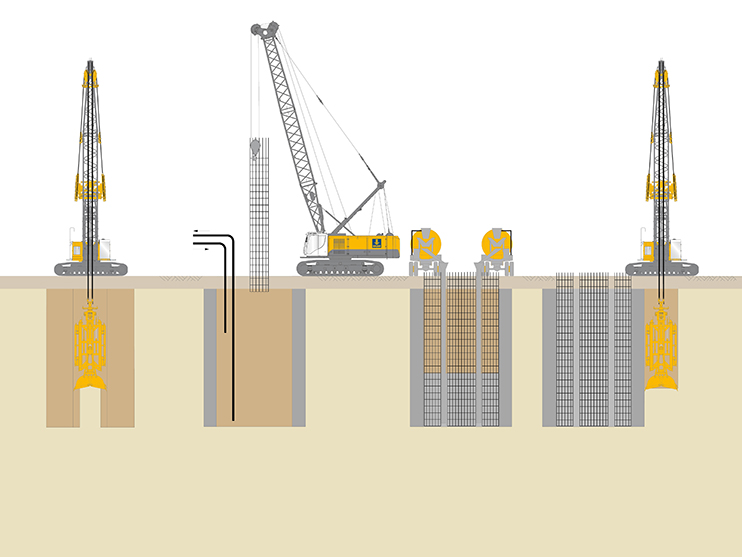

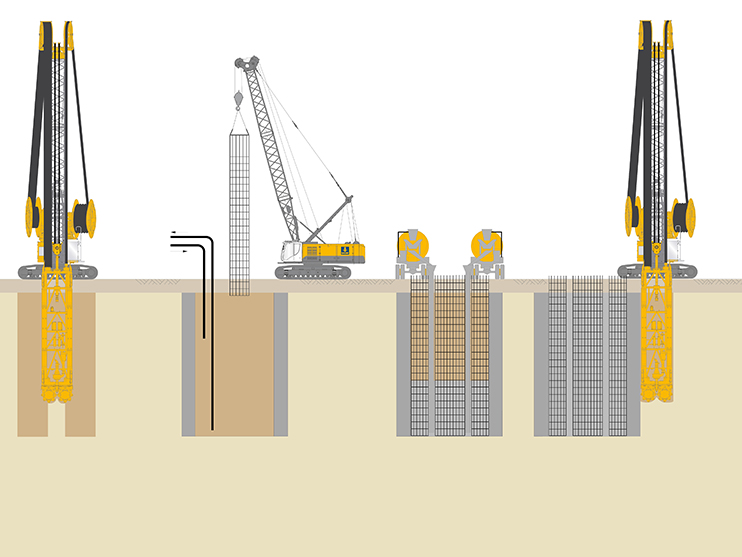

Diaphragm walls have a static and/or sealing function and can serve as cut-off walls for dams or excavation pits, as foundations or as enclosures of below-ground structures. They are executed as concrete or steel-reinforced concrete walls, built from ground level. They are considered very resistant to deformation and virtually water-impermeable. They are excavated in sections by duty-cycle cranes using suitable diaphragm wall grabs or cutters, with the aid of a stabilizing fluid, between previously fabricated guide walls, which serve primarily to guide the grab or cutter, allow fluctuations in level of the stabilizing fluid and carry temporary loads from the reinforcement or stop end elements. When the final depth is reached, temporary or permanent stop ends are installed in the trench, the stabilizing fluid is desanded and reinforcement cages are installed. Then concrete is poured through the Tremie pipes.

In the course of excavating the adjoining panel, temporary stop ends are removed for re-use.

Types of Construction Method

Two different grab systems (mechanical and hydraulic), suitable for wall thicknesses of 600 to 1,500mm, are available for trench excavation.

The grab is lowered into the trench and the soil is discontinuously transported. Larger blocks or sections of rock are punched through, excavated or displaced using modified grabs or heavy-duty chisels. Measuring systems can be installed to verify verticality.

On mechanical grabs, a rope and pulley system operates the jaws. To increase the closure force, the closing cable is reeved five to six times. Hydraulic grabs work with a hydraulic cylinder. They have very high closure forces and work with lower noise and less vibrations than mechanical grabs.

Trench cutters are used to produce diaphragm walls in thicknesses of 630 to 3,200mm. As they transport the spoil continuously, they are particularly suitable for depths of more than 40m. Trench cutters operate with two counter-rotating cutter wheels which, depending on configuration, are suitable for a wide variety of strata, including even ultra-hard rock. The soil material is cut by the rotation of the wheels, crushed, mixed with slurry and transported to the surface by a suction pump.

Hydraulic steering flaps control the cutter in both horizontal directions. The penetration depth and speed are regulated by controlled activation of the cutter weight.